Electrical Motor Braking

Drive dynamic braking

Drive Dynamic braking is a method to slow down a servo system by dissipating the mechanical energy driven by the motor back EMF.

|

Drive dynamic braking is not functional safe. |

The AKD2G has a built in advanced drive dynamic braking mode which operates fully in hardware. When activated, the drive powers the motor terminals with voltages to maximize the stopping force per amount of motor current. This advanced method forces all of the dynamic braking current to be stopping current and insures the fastest stopping per ampere of motor terminal current.

- When current is not being limited, the mechanical energy is being dissipated in the motor winding resistance.

- When current is being limited, energy is returned to the drive bus capacitors.

- The drive also limits the maximum dynamic braking motor terminal current by using the AXIS#.DBILIMIT parameter to insure that the drive, motor, and customer load do not see excessive currents/forces.

Whether and how the AKD2G uses dynamic drive braking depends on (AXIS#.DISMODE).

Regeneration braking

When the amount of returned energy from the motor builds the bus capacitor voltage up enough the drive activates the regenerative braking circuit to start dumping the returned energy in the regen resistor (also called regenerative resistor or brake resistor).

|

External regen resistors are described in the regional Accessories Manual. |

Functional description

1. Individual drives, not coupled through the DC bus link circuit (+DC, -DC)

When the energy fed back from the motor has an average or peak power that exceeds the preset level for the brake power rating, the drive generates the warning "W2010 Regen Energy Critical”. If the power exceeds the set fault level, the regenerative circuit will switch off and the drive will disable.

2. Several drives coupled through the DC bus link (+DC, -DC)

Using the built-in regenerative circuit, several drives of the same series can be operated from a common DC-bus link (see "DC Bus link connector X3/X3B"), without any additional measures. 90% of the combined power of all the coupled drives is always available for peak and continuous power. If the power of the drive with the lowest switch-off threshold (resulting from tolerances) exceeds the set fault level, the regenerative circuit will switch off on that drive.

Switch-off on over voltage: With the regenerative circuit switched off, the returned energy is not dissipated and therefore the DC-bus link level increases. The drive reports an over-voltage fault if the DC-bus voltage threshold is exceeded. When this happens, the drive power stage is immediately disabled and the load coasts to a stop with the fault message “F2006 Bus Over voltage".

The ready to operate contact (terminals X21/B5-B6) is opened (see "Digital-Out 9, Relay contacts").

|

Observe the regeneration time (some minutes) after full load with peak brake power. |

Technical data for AKD2G-Sxx-6V

Technical data for the regenerative circuit depends on the drive type and the mains voltage. Supply voltages, capacitance, and switch-on voltages are all nominal values.

|

Brake circuit |

AC Supply |

||

|---|---|---|---|

|

AKD2G-Sxx- |

Rated data |

Units |

120V / 240V |

|

6Vxxy |

Regen start voltage at rated supply voltage |

V |

380 |

|

Overvoltage limit |

V |

420 |

|

|

Maximum regenerative duty cycle |

% |

35* |

|

|

Internal regen resistor |

Ω |

15 |

|

|

Continuous power, internal resistor |

W |

100 |

|

|

Peak brake power, internal resistor (0.5s) |

kW |

3 / 9 |

|

|

External regen resistor (recommended 15 Ω) |

Ω |

≥10 |

|

|

Continuous brake power, external resistor |

kW |

3 |

|

|

Peak brake power, external (1s) |

kW |

5 / 14 |

|

|

6V03S, 6V06S |

Absorption energy in capacitors (±20%) |

Ws |

6 / 23 |

|

DC Bus Capacitance |

µF |

1640 |

|

|

6V12S, 6V03D, 6V06D |

Absorption energy in capacitors (± 20%) |

Ws |

9 / 35 |

|

DC Bus Capacitance |

µF |

2460 |

|

* depends on connected regen resistor power.

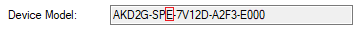

Technical data for AKD2G-Sxx-7V

Technical data for the regenerative circuit depends on the drive type and the mains voltage. Supply voltages, capacitance, and switch-on voltages are all nominal values.

|

Brake circuit |

AC Supply |

|||

|---|---|---|---|---|

|

AKD2G-Sxx- |

Rated data |

Units |

240V |

400V/480V |

|

7V03S ,7V06S, 7V12S, 7V03D, 7V06D |

Regen start voltage at rated supply voltage |

V |

380 |

633 / 760 |

|

Overvoltage limit |

V |

420 |

840 |

|

|

Maximum regenerative duty cycle |

% |

35* |

||

|

Internal regen resistor |

Ω |

33 |

||

|

Continuous power, internal resistor |

W |

100 |

||

|

Peak brake power, internal resistor (0.5s) |

kW |

4 |

17 |

|

|

External regen resistor (recommended 33 Ω) |

Ω |

≥25 |

||

|

Continuous brake power, external resistor |

kW |

2 |

6 |

|

|

Peak brake power, external (1s) |

kW |

6 |

24 |

|

|

7V03S, 7V06S |

Absorption energy in capacitors (±20%) |

Ws |

3 |

30 / 18 |

|

DC Bus Capacitance |

µF |

235 |

||

|

7V12S, 7V03D, 7V06D |

Absorption energy in capacitors (±20%) |

Ws |

6 |

50 / 35 |

|

DC Bus Capacitance |

µF |

470 |

||

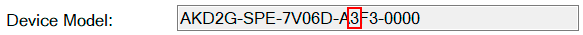

AKD2G-Sxx-7V24

|

Brake circuit |

AC Supply |

|||

|---|---|---|---|---|

|

AKD2G-Sxx- |

Rated data |

Units |

240V |

400V/480V |

|

7V24S

|

Regen start voltage at rated supply voltage |

V |

380 |

633 / 760 |

|

Overvoltage limit |

V |

420 |

840 |

|

|

Maximum regenerative duty cycle |

% |

35* |

||

|

Internal regen resistor |

Ω |

15 |

||

|

Continuous power, internal resistor |

W |

140 |

||

|

Peak brake power, internal resistor (0.5s) |

kW |

9 |

38 |

|

|

External regen resistor (recommended 15 Ω) |

Ω |

≥10 |

||

|

Continuous brake power, external resistor |

kW |

3 |

10 |

|

|

Peak brake power, external (1s) |

kW |

14 |

55 |

|

|

Absorption energy in capacitors (±20%) |

Ws |

15 |

125 / 80 |

|

|

DC Bus Capacitance |

µF |

1200 |

||

* depends on connected regen resistor power.